Shrinkage Characteristics of FORCE 10,000® Concrete – TB-0708

FORCE 10,000D® concrete is typically used in applications where cracking may be a major concern. These include environments that are highly corrosive, chemically saturated, or very abrasive and where less permeable, more durable concrete is required. For these applications concrete needs to be designed and constructed to produce the least amount of cracking.

A series of tests was conducted to examine the shrinkage characteristics of FORCE 10,000D® concrete as it relates to aggregates, plain concrete and length of curing. The evaluations included several mix designs with silica fume dosage rates ranging from 0 to 10.8% by weight of cement. The concrete was sampled, prepared, cured and tested in accordance with ASTM C157, “Length Change of Hydraulic Cement Concrete.”

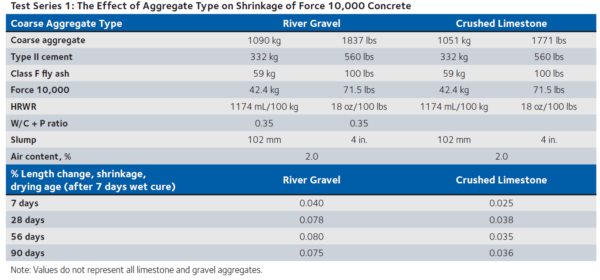

Test Series 1: The Effect of Aggregate Type on Shrinkage of FORCE 10,000® Concrete

| Coarse Aggregate Type | River Gravel | Crushed Limestone | ||

|---|---|---|---|---|

| Coarse aggregate | 1090 kg | 1837 lbs | 1051 kg | 1771 lbs |

| Type II cement | 332 kg | 560 lbs | 332 kg | 560 lbs |

| Class F fly ash | 59 kg | 100 lbs | 59 kg | 100 lbs |

| FORCE 10,000® | 42.4 kg | 71.5 lbs | 42.4 kg | 71.5 lbs |

| HRWR | 1174 mL/100 kg | 18 oz/100 lbs | 1174 mL/100 kg | 18 oz/100 lbs |

| W/C + P ratio | 0.35 | 0.35 | ||

| Slump | 102 mm | 4 in. | 102 mm | 4 in. |

| Air content, % | 2.0 | 2.0 | ||

| % Length change, shrinkage, drying age (after 7 days wet cure) |

River Gravel | Crushed Limestone | ||

| 7 days | 0.040 | 0.025 | ||

| 28 days | 0.078 | 0.038 | ||

| 56 days | 0.080 | 0.035 | ||

| 90 days | 0.075 | 0.036 | ||

Note: Values do not represent all limestone and gravel aggregates.

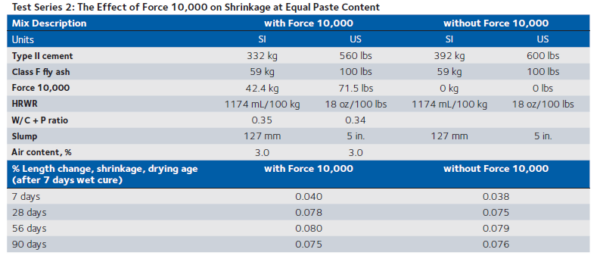

Test Series 2: The Effect of FORCE 10,000® on Shrinkage at Equal Paste Content

| Mix Description | with FORCE 10,000® | without FORCE 10,000® | ||

|---|---|---|---|---|

| Units | SI | US | SI | US |

| Type II cement | 332 kg | 560 lbs | 392 kg | 600 lbs |

| Class F fly ash | 59 kg | 100 lbs | 59 kg | 100 lbs |

| FORCE 10,000® | 42.4 kg | 71.5 lbs | 0 kg | 0 lbs |

| HRWR | 1174 mL/100 kg | 18 oz/100 lbs | 1174 mL/100 kg | 18 oz/100 lbs |

| W/C + P ratio | 0.35 | 0.34 | ||

| Slump | 127 mm | 5 in. | 127 mm | 5 in. |

| Air content, % | 3.0 | 3.0 | ||

| % Length change, shrinkage, drying age (after 7 days wet cure) |

with FORCE 10,000® | without FORCE 10,000® | ||

| 7 days | 0.040 | 0.038 | ||

| 28 days | 0.078 | 0.075 | ||

| 56 days | 0.080 | 0.079 | ||

| 90 days | 0.075 | 0.076 | ||

Test Series 3: The Effect of Curing on Shrinkage of FORCE 10,000® Concrete

| Mix Description | Midwest Gravel | Northeast Gravel | Midwest Limestone |

|---|---|---|---|

| W/C + P ratio | 0.37 | 0.37 | 0.37 |

| FORCE 10,000® | 27.2 kg (46 lbs) | 27.2 kg (46 lbs) | 27.2 kg (46 lbs) |

| HRWR | 652 mL/100 kg (10 oz/100 lbs) | 652 mL/100 kg (10 oz/100 lbs) | 652 mL/100 kg (10 oz/100 lbs) |

| Slump | 165 mm (6.5 in.) | 165 mm (6.5 in.) | 165 mm (6.5 in.) |

| Air content, % | 6% | 6% | 6% |

| % Length change (shrinkage) wet cure time, days | |||

| 3 days | 0.075 | 0.084 | 0.051 |

| 7 days | 0.061 | 0.068 | 0.045 |

| 28 days | 0.040 | 0.048 | 0.038 |

Conclusions

- The type of aggregate used in the mix will influence the amount of shrinkage.

- FORCE 10,000® has little effect on shrinkage when compared to concrete made without silica fume with equal paste content. ACI 234 indicates that the drying shrinkage of silica fume concrete is generally comparable to that of control concrete regardless of the water/cementitious ratio.